Flexo Printing Press

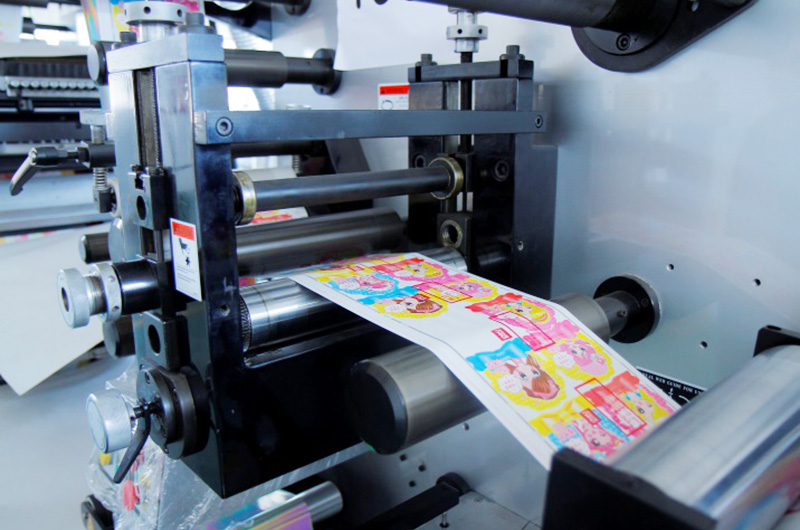

Flexo printing falls under the letterpress printing category and offers more versatility by combining other processes such as laminating, varnishing, rotary silk screen printing and embossing for processing complicated substrates and inks.

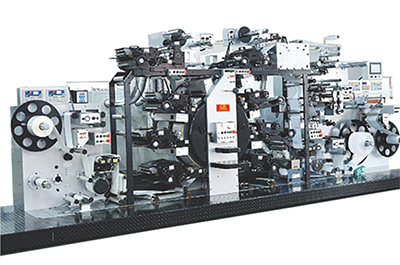

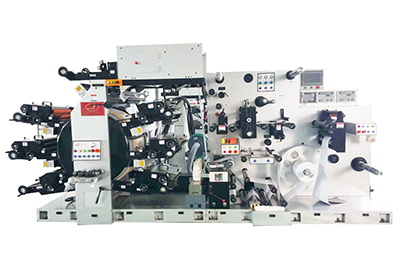

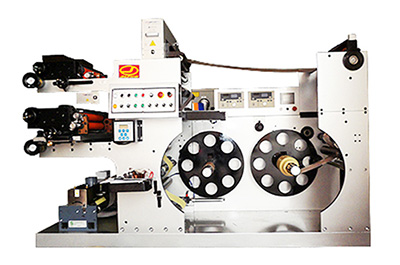

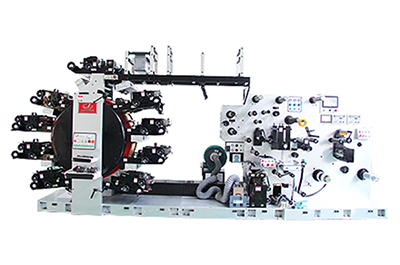

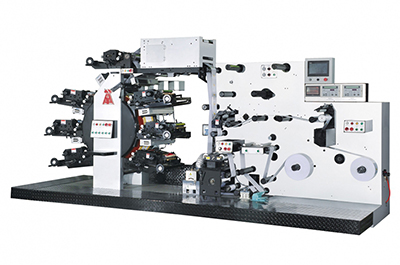

Just about any materials that are easy to roll up are capable of being handled using Jin Xiang label presses, including paper label printing, foil label printing, film printing, metallic label printing and more. We also offer bespoke flexo presses that offer a variety of printing colors, engine power, machine sizes and equipment configurations to meet your needs. Shown below are the flexo printing presses we have previously made.

-

- JX-260R7C+1

Varnish station: 7-color printing machine 1sets

Max. Web width: 250mm

Max. Print length:460mm

-

- JX-460R6C+1 / JX-260R6C+1

Varnish station:6-color printing machine JX-6C460 1sets

Max. Web width: 450mm

Max. Print length:460mm

-

- JX-260R2C

Varnish station: 6-color printing machine JX-6C260 1sets

Max. Web width: 250mm

Max. Print length:460mm

-

- JX-260R1C

Varnish station: 1-color printing machine JX-260R1C

Max. Web width: 250mm

Max. Print length:650mm

-

- JX-260R8C+1

Varnish station:8-color printing machine JX-260R8C+1 1sets

Max. Web width: 250mm

Max. Print length:460mm

-

- JX-6C380R

Varnish station: 6-color printing machine JX-6C380R 1sets

Max. Web width: 450mm

Max. Print length:460mm

In order to ensure the printing accuracy under long-term high speed operation, a tension controller is installed on the top of equipment. Operators adjust the tension according to the material and thickness of printing substrates.

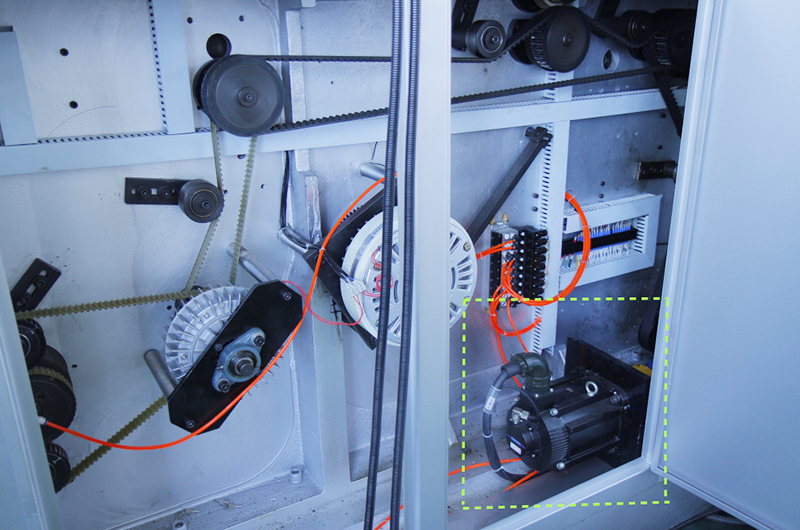

Only one main motor is required to power the whole equipment. Then the power is transferred to each printing unit precisely through the gearing, allowing all units with consistent and stable printing speed and producing more accurate printing effect. Our label press is driven by original Yaskawa servo motors.

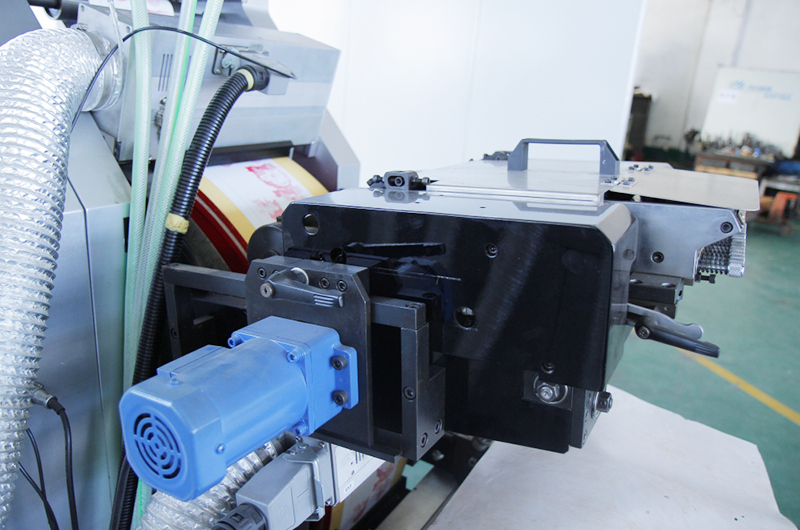

PVC, BOPP and other films are not easy for the ink to adhere due to the smooth surface, which affects the printing effect. Before printing, the corona treatment is helpful to enhance the adhesion of ink on materials, thus providing better printing effect. JIN XAING label press is ideal to print on various materials.

The original America FIFE web guide controller allows for more accurate printing. During material feeding, the materials are not aligned for long-term transferring and the generated slight vibration will also cause deviation of position, thus leading to poor printing effect. Web guide controller can be equipped to correct the lateral deviation of the printing material in its forward motion.

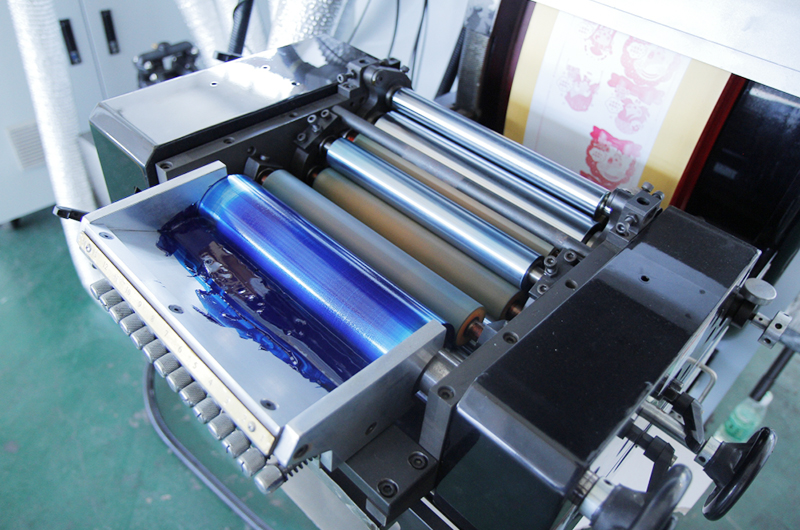

Each group of ink fountain roller contains 7 ink rolls. The ink is very sticky and direct inking will influence the printing effect. The process of ink distributing makes the ink to be adhered uniformly on the surface of printed materials.

In changing ink, a scraper is needed to clean the ink on ink foundation roll so as to ensure precise printing color. Each printing unit equips an individual motor to drive the scraper for cleaning operation independently.

Manual inking is applied.

UV drying unit is commonly used. A power-saving LED drying is also optional. Due to the weak adhesion of dried ink, LED drying is not recommended for substrates requiring varnishing process.

Varnishing unit is set after the printing unit, requiring the configuration of an UV drying unit. Varnishing offers more colorful and brighter printed pattern.

Die cutter can be installed to cut the waste of printed materials before rewinding operation.

When the printing is finished and before rewinding, a protective layer can be laminated on this unit to protect the patterns from scratching.

This unit performs the task of reverse printing.

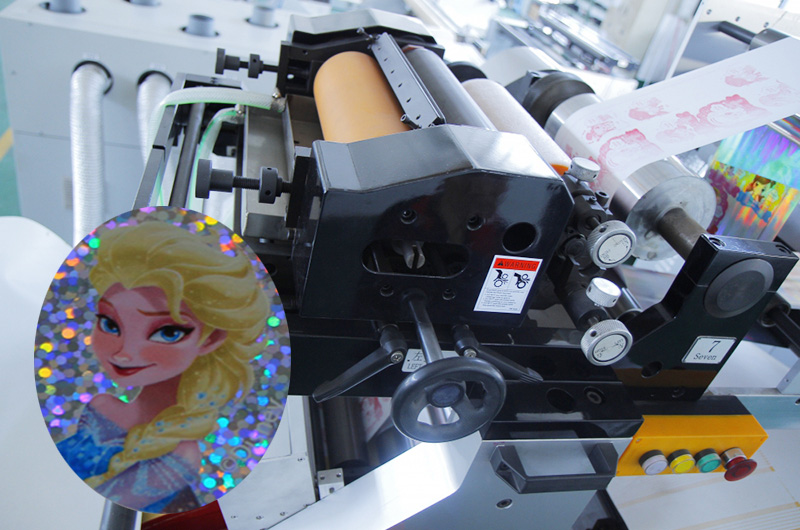

Ink cannot deploy metallic colors of golden and silver and gold ink costs a lot. Here the cold foil system is helpful to print metallic golden and silver patterns.

This printing unit offering materials of 3-D dimensional and embossing effect.

This accommodates to customers requiring gravure printing or digital printing.

Cutting off or into a required shape: it is ideal for customers to cut the printed material off or into different shapes.

Static observation system facilitate operators to check out the accuracy of patterns under high speed operating.

Materials like plastic film are easy to deform and even stick together after drying. So the cooling process is necessary.

Plastic film is easy to generate static during the printing process, causing operation obstruction and even accident. Electrostatic eliminator helps the material to achieve an ionizing balance (equality of positive and negative ions) to eliminate electrostatic.

Lamination unit is suitable for customers to fold the printed materials.

- Tel.:+86-13829126249

- E-mail:jhliwen@126.com