Fold mask production machine

Our fold mask production machine is applied to the production of 3–5 layers fold masks, using ultrasonic to bond layers of non-woven raw fabric, activated carbon and filter material and then cutting forming the mask body. Then, use the ear loop welding machine to weld the ear loop to the body to finish the mask making.

Process

-

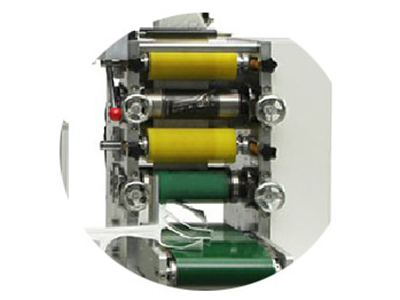

Fabric Welding

Fabric Welding -

Folding forming

Folding forming -

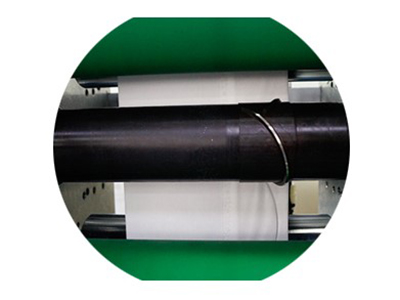

Roll cutting

Roll cutting -

Finished product output

Finished product output

Parameters

| Mask type | N95, KN95, FFP1, FFP2, FFP3 |

| Capacity | 45-55pcs/min |

| Applied materials | Non-woven fabric |

| Lays number | 3–5 layers |

| Processing method | Ultrasonic |

| Voltage | AV220V,50HZ |

| Installed power | 7.0KW |

| Control | PLC/HMI |

| Air pressure | 0.4-0.6MPa |

| Size | L5500*W1300*H2000(mm) |

| Weight | ≤2500KG |

Main configuration

| Item | Brand |

| PLC/HMI | CHINA/Panasonic |

| Ultrasonic | CHINA Blue Whale |

| Servo | Inovance |

| Bearing slide block | NSK/HIWIN |

| Pneumatic fittings | Airtac |

| Switching power | Schneider/delixi |

| Sensor | Panasonic/omron |

Video

- Tel.:+86-13829126249

- E-mail:jhliwen@126.com